Forside / Conveyor Belt Fasteners

Would you like to see our prices with or without VAT?

Excl. VAT

VAT included

Showing all 13 resultsSorted by latest

We often have the item even if it is not added to the webshop!

– Don’t hesitate to contact us, we can almost always get your spare parts.

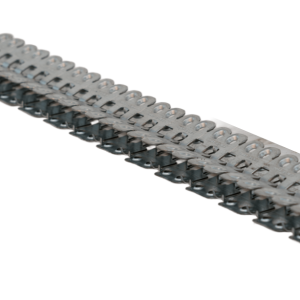

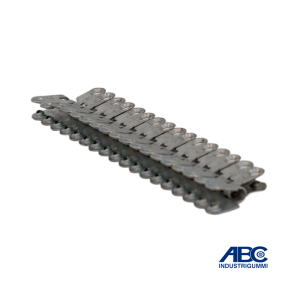

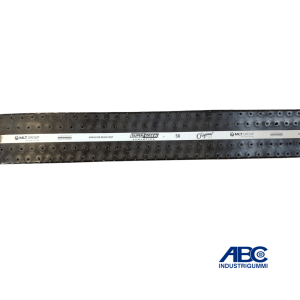

Our mechanical belt fasteners ensure quick and efficient splicing of conveyor belts – whether you need a temporary fix or a permanent connection. We offer fasteners for a wide range of belt types, including rubber, PVC, and PU, so you can always find a solution that fits your operation.

Designed for easy installation, high durability, and flexibility, our belt fasteners are suitable for use across various industries such as manufacturing, waste handling, agriculture, and construction. They help minimize downtime and provide a secure splice that withstands demanding environments.

Whether you’re working with light-duty or heavy-duty conveyor belts, we have a fastening solution to match. Explore our selection and find the right option for your setup.

Buying Guide – How to Choose the Right Belt Fastener

When selecting a mechanical belt fastener for your conveyor, consider the following factors:

1. Belt Type

Rubber belts: Choose a fastener that can handle the belt’s flexibility and wear resistance.

PVC and PU belts: Require a fastener that ensures a tight seal without damaging the material.

2. Load and Operation

Light-duty: Standard fasteners are often sufficient.

Medium to heavy-duty: Choose a reinforced fastener that can handle high loads and abrasive materials.

3. Installation Time and Tools

Quick installation: Opt for a fastener that can be mounted with hand tools to reduce downtime.

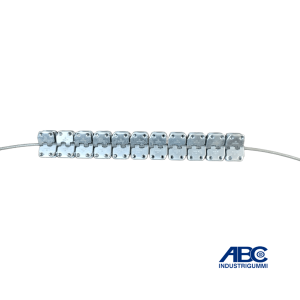

Fastening method: Some fasteners require bolts, screws, or locking clips – choose what suits your needs best.

4. Temporary or Permanent Solution

Temporary repair: Quick-install fasteners are ideal for emergency repairs.

Permanent splice: Go for a more robust fastener with enhanced wear resistance for long-term use.

Need help selecting the right belt fastener? Contact us – we’re happy to guide you to the optimal solution.

Installation Guide – How to Install a Mechanical Belt Fastener

Tools you’ll need:

✔ Wrench or socket spanner

✔ Allen key (depending on fastener type)

✔ Screws and locking clips

✔ Measuring tape

✔ Knife or scissors (to trim belt ends)

Step-by-step instructions:

1. Prepare the belt

Stop the conveyor and secure the area.

Cut both belt ends straight for an even splice.

Clean off any dust or debris.

2. Position the fastener

Place the fastener between the two belt ends.

Make sure it’s aligned to avoid mis-tracking.

3. Secure the fastener

Insert bolts, screws, or clips and tighten evenly.

Use a cross-pattern when tightening to ensure uniform pressure.

4. Check the connection

Verify the fastener is firmly in place without bending or deforming the belt.

Manually rotate the conveyor to ensure smooth operation.

5. Start and test

Start the conveyor at low speed and observe the splice.

If it vibrates or makes noise, re-tighten or adjust as needed.

⚠ Important: Regularly inspect the splice for wear and retighten screws as needed.

Opening hours:

Monday to Friday: 7.00 – 16.00

On Saturdays, Sundays and holidays, our 24/7 service is available.

Information

Customer service

ABC Industrigummi ApS - CVR: DK14711198