Forside / Cleaning and maintenance

Would you like to see our prices with or without VAT?

Excl. VAT

VAT included

Showing all 37 resultsSorted by latest

We often have the item even if it is not added to the webshop!

– Don’t hesitate to contact us, we can almost always get your spare parts.

Effective cleaning and proper maintenance of conveyor systems are essential for ensuring stable operations and preventing unnecessary breakdowns. By keeping the conveyor belt free of material build-up and debris, you reduce wear and significantly extend the service life of your system. At the same time, you minimize the risk of production stoppages and improve overall workflow efficiency.

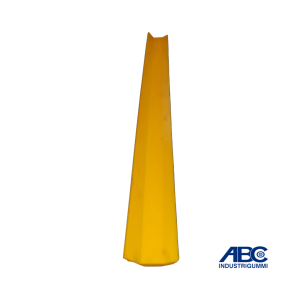

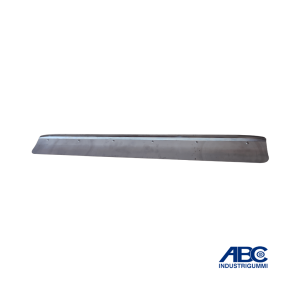

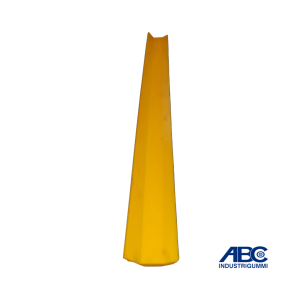

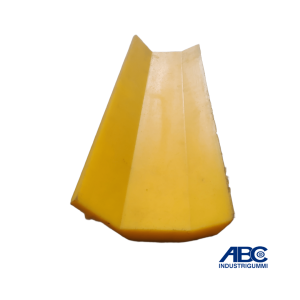

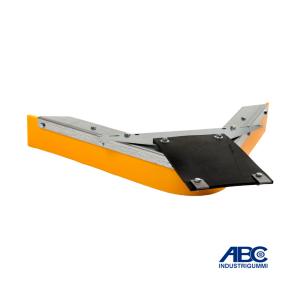

Solutions such as belt scrapers, belt brushes, and PU plows play a key role in cleaning conveyor belts. These tools help remove residual materials like soil, gravel, stones, and other deposits that could otherwise cause damage or reduce performance.

With regular inspections and maintenance, you can detect potential issues early and reduce operating costs. It’s about combining the right cleaning tools with a maintenance plan that suits your operation – whether you work in heavy industry, waste management, or agriculture.

Save time and money by optimizing the cleaning of your conveyor system. With the right solutions, you can ensure smooth operation and meet the demands of modern production environments.

1. Why is conveyor belt cleaning important?

Cleaning prevents material build-up that can cause wear, damage, and production downtime. It also improves safety and operational efficiency.

2. How often should a conveyor belt be maintained?

It depends on operating conditions. Generally, a daily visual inspection is recommended, with thorough cleaning and servicing scheduled quarterly.

3. What are the most common tools for cleaning conveyor belts?

The most commonly used tools include belt scrapers, belt brushes, and PU plows – each designed to remove different types of materials and deposits from the belt surface.

4. How can I reduce wear on my conveyor belt?

Regular cleaning, proper adjustment of scrapers, and routine belt inspections are key. Choosing high-quality cleaning equipment also helps prevent unnecessary strain on the belt.

5. Can cleaning and maintenance extend the belt’s service life?

Yes, proper maintenance can significantly extend the lifespan of your conveyor belt and reduce the need for costly repairs or replacements.

Opening hours:

Monday to Friday: 7.00 – 16.00

On Saturdays, Sundays and holidays, our 24/7 service is available.

Information

Customer service

ABC Industrigummi ApS - CVR: DK14711198