Forside / Impact-absorbing components

Would you like to see our prices with or without VAT?

Excl. VAT

VAT included

Showing all 7 resultsSorted by latest

We often have the item even if it is not added to the webshop!

– Don’t hesitate to contact us, we can almost always get your spare parts.

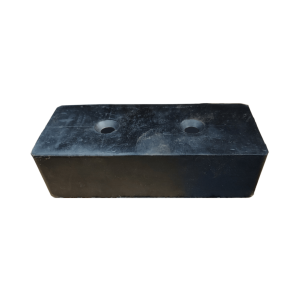

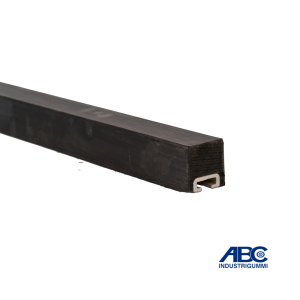

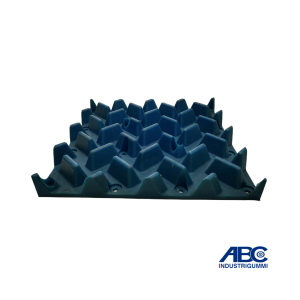

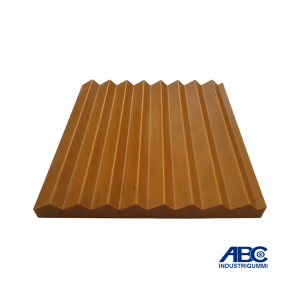

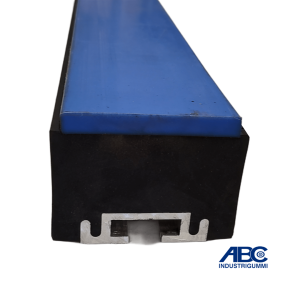

When heavy materials are loaded onto a conveyor belt, it’s crucial to protect the belt from damage. This is where shock-absorbing elements and impact bars – such as impact rails and rollers – come into play. They are installed under the belt at the loading point to absorb impact, reduce friction, and prevent belt damage. At the same time, they help the belt run smoothly, even under heavy loads.

There are two main types of shock-absorbing components: rails and rollers. Each has its own advantages, and the best choice depends on your specific application:

The right choice depends on your production environment and the weight of the materials. For high-impact or heavy-duty applications, impact rails may be the best option due to their durability. If low friction and energy efficiency are key priorities, impact rollers may be the better choice – especially when handling evenly distributed materials.

Choosing the right shock-absorbing elements not only protects your conveyor belt but also ensures stable operation and lowers maintenance costs.

| Type | Advantages | Disadvantages |

|---|---|---|

| Rails | – Very durable, even under heavy loads | – Light friction may slightly increase energy use |

| – Creates a tight seal between belt and skirting, reducing material spillage | – Less energy-efficient than rollers | |

| – Best suited for uneven and heavy materials | ||

| Rollers | – Low friction reduces energy consumption | – Can be damaged under very heavy impact |

| – Ensures smooth belt movement even under load | – Risk of material spillage between rollers if not spaced correctly | |

| – Energy-efficient and ideal for evenly distributed materials | – Less durable than rails in high-impact applications |

Opening hours:

Monday to Friday: 7.00 – 16.00

On Saturdays, Sundays and holidays, our 24/7 service is available.

Information

Customer service

ABC Industrigummi ApS - CVR: DK14711198