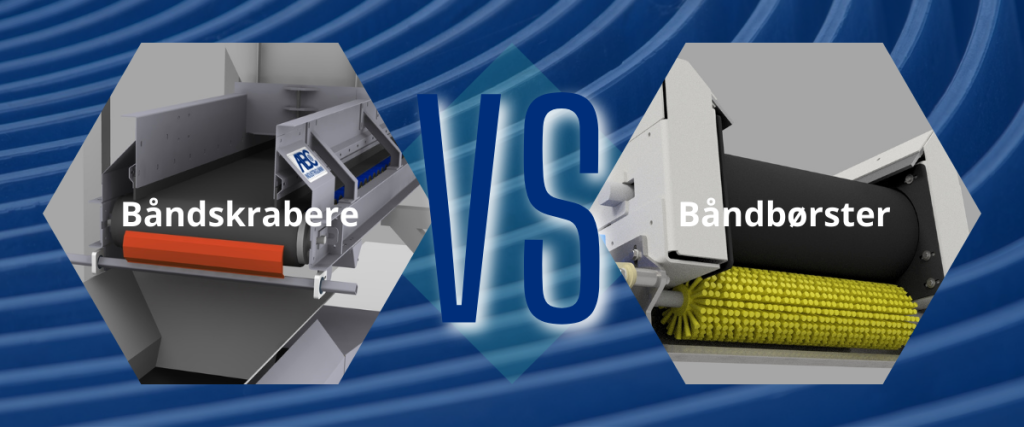

When it comes to cleaning and maintaining conveyor belts, choosing the right system is crucial for both operational reliability and belt life. One of the most commonly used solutions is belt scrapers – but now belt brushes have also entered the market.

In this article, we review the advantages and disadvantages of both types so you can make the right choice.

Belt scrapers are mechanical devices installed at the drum to remove embedded debris from the surface of the conveyor belt. They are typically used in environments where material tends to stick, such as in the concrete, stone, agricultural and recycling industries.

✅ High cleaning efficiency – Belt scrapers effectively remove both wet and dry materials, reducing buildup on the conveyor belt.

✅ Reduced wear on the belt – By keeping the conveyor belt clean, the risk of damage is reduced, which extends the life of the belt.

✅ Minimizes downtime – An efficient scraper minimizes material buildup that can lead to unplanned downtime and increased maintenance costs.

✅ Different types for different needs – There are both primary and secondary scrapers that can be combined for an even better cleaning effect.

Find the selection of belt scrapers on our webshop here.

❌ Can wear out the belt – If not properly adjusted or maintained, scrapers can cause unnecessary friction, which can cause unnecessary wear on the conveyor belt.

❌ Not ideal for all material types – Very fine or dry materials, such as dust or light particles, can be difficult to remove with a scraper.

❌ Requires regular maintenance – Scraper blades need to be adjusted and replaced periodically to maintain efficiency.

❌ Does not work with carrier belts – If your conveyor belt has carriers on it, a belt scraper is not ideal.

Belt brushes work by rotating and brushing debris away from the conveyor belt. They are particularly effective at removing fine materials such as sawdust, sand, dust and powder products that may otherwise become stuck to the surface.

✅ Works with carrier belts – As previously mentioned, belt scrapers are not ideal for carrier belts, but belt brushes are, as the brushes can get in between the carriers.

✅ Gentle on the conveyor belt – Unlike belt scrapers, the brushes create less friction, reducing wear on the belt.

✅ Effective for fine materials – Ribbon brushes can remove small particles that may otherwise be difficult to scrape away.

✅ Flexible installation – They can be mounted in multiple locations along the conveyor belt, including both on the underside and along the edges, where accumulation often occurs.

✅ Low maintenance – The brushes generally have a longer lifespan than scraper blades and require less adjustment.

❌ Less effective on stubborn dirt – If the material is sticky or compact, a brush will often not be sufficient to completely clean the belt.

❌ May lose effectiveness over time – The brushes become worn and can lose their cleaning ability, which may require replacement or cleaning.

❌ Not ideal for wet materials – When handling wet or muddy materials, brushes can become clogged and lose their effectiveness.

The choice between belt scrapers and belt brushes depends on several factors, such as material type, operating environment, belt type and maintenance budget.

✔️ Your conveyor belt handles sticky or compact materials (e.g. clay, soil, cement or wet waste).

✔️ You want a powerful solution to prevent material buildup and downtime.

✔️ You have the opportunity to perform regular adjustment and maintenance.

✔️ Your conveyor belt transports fine materials such as dust, sand or sawdust.

✔️ Your conveyor belt is a carrier belt.

✔️ You want a more gentle cleaning solution with lower wear on the belt.

✔️ You work in an environment where the belt does not become heavily coated with dirt.

In many cases, the best solution is a combination of both systems. A belt scraper can remove most of the coarse material, while a brush can subsequently take care of the fine particles. This ensures the most efficient cleaning and a longer life of the conveyor belt.

At ABC Industrigummi, we offer both belt scrapers and belt brushes as well as advice on the optimal solution for your specific needs.

Contact us today for a no-obligation chat about how we can optimize your conveyor belt cleaning!

📞 Call +45 57 53 70 01 or send an email to abc@abc-industrigummi.dk.

Kenneth Saxtorph

If you have a question or need help, you are more than welcome to contact us at:

Opening hours:

Monday to Friday: 7.00 – 16.00

On Saturdays, Sundays and holidays, our 24/7 service is available.

Information

Customer service

ABC Industrigummi ApS - CVR: DK14711198